What is Logistics? Complete Guide to Supply Chain Management from China to Japan 2025

著者: Guanwutong / November 9, 2025

When businesses begin importing goods from China to Japan, they encounter a critical question: what is logistics? Many assume logistics simply means “shipping products from point A to point B.” This fundamental misunderstanding leads to costly mistakes, delayed shipments, and wasted resources. In reality, logistics encompasses a far broader and more complex set of activities that determine whether your supply chain succeeds or fails.

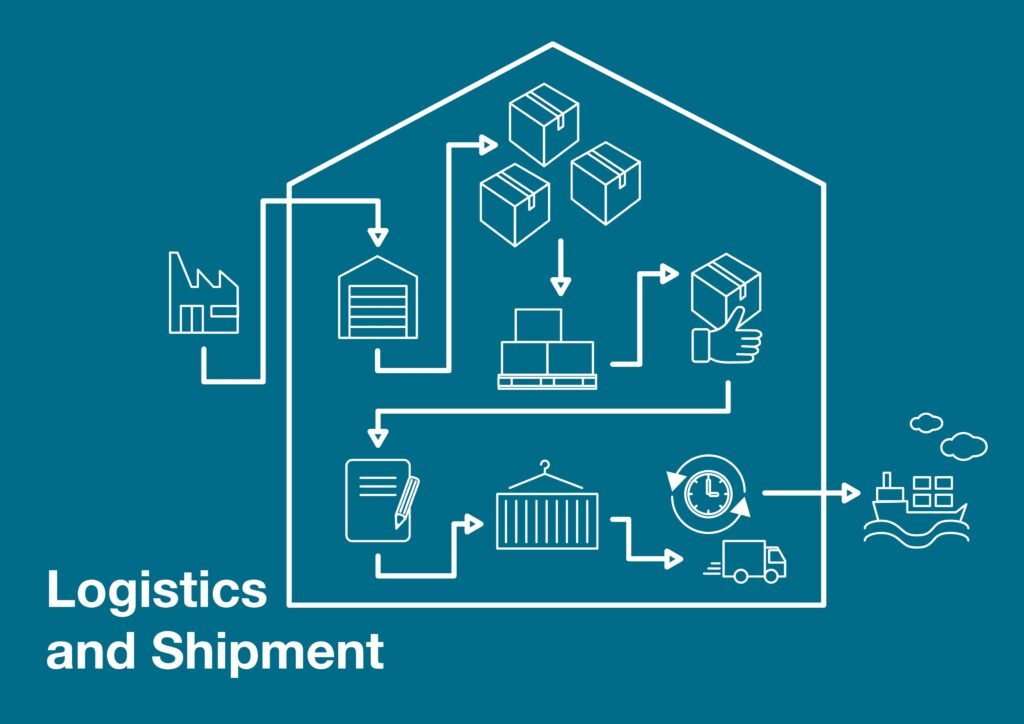

What is logistics fundamentally? Logistics is the comprehensive management of the flow of goods, information, and resources from the point of origin (manufacturing facilities in China) through intermediary storage points to the final destination (distribution centers or retail locations in Japan). It represents the orchestrated coordination of multiple functions—transportation, warehousing, packaging, information management, and value-added services—working together to deliver products efficiently, cost-effectively, and on time.

Understanding what logistics means for China-to-Japan trade is essential for importers of electronics, textiles, furniture, automotive components, and consumer goods. The logistics industry for trade between these two nations is valued at over ¥32 trillion annually and continues growing as e-commerce accelerates and supply chains become increasingly complex.

This guide explores what logistics is, its six core functions, how it differs from simple freight forwarding, and how to optimize logistics operations for your China-Japan import business.

1. What is Logistics? Definition and Core Concept

To understand what logistics means in modern business, we must move beyond simplistic definitions. Logistics is the detailed organization and execution of the complex movement of goods, services, and information through the supply chain. More precisely, logistics involves:

Planning: Forecasting demand and designing the optimal supply chain pathway.

Sourcing: Identifying suppliers and arranging procurement.

Execution: Managing the physical movement, storage, and handling of goods.

Visibility: Tracking shipments and maintaining real-time information.

Optimization: Continuously improving efficiency and reducing costs.

What Does Logistics Include?

Many business owners ask, “What exactly does the term logistics encompass?” The answer is surprisingly broad:

In-bound Logistics: Movement of raw materials from suppliers (China) to manufacturing or distribution facilities.

Outbound Logistics: Movement of finished goods from warehouses to customers (Japanese retailers, distributors, or end-users).

Internal Logistics: Movement and storage of goods within warehouses and distribution centers.

Return Logistics: Management of product returns, recycling, and reverse supply chains.

Logistics vs. Transportation: What is the Difference?

This is where confusion typically begins. Many people use “logistics” and “transportation” interchangeably, but they are distinctly different:

Transportation focuses narrowly on moving goods from one location to another—essentially the trucking, shipping, or air freight component.

Logistics encompasses transportation PLUS warehousing, inventory management, packaging, information systems, demand forecasting, and coordination of all these elements into one seamless operation.

Think of it this way: transportation is one component of logistics. Logistics is the comprehensive system. When importing from China to Japan, you need logistics management, not just a shipping company.

What is Logistics in the Context of China-Japan Trade?

For companies engaging in import-export operations between China and Japan, logistics becomes a critical competitive advantage. The complexity is extraordinary:

Coordination across international borders with different regulatory systems.

Management of multiple transportation modes (ocean freight, air freight, and trucking).

Customs clearance and documentation in two countries.

Real-time visibility across a 10-15 day transit window.

Cost optimization amid volatile shipping rates and seasonal fluctuations.

Effective logistics management between these two trading partners can reduce costs by 15-25%, accelerate delivery by 2-3 days, and eliminate 90% of customs-related delays.

2. The 6 Core Functions of Logistics

What are the six major functions of logistics? Modern logistics, particularly for China-Japan trade, relies on six interconnected functions. Understanding each is essential to comprehending “what is logistics” in practical terms.

Function 1: Transportation & Distribution

Definition: The physical movement of goods from origin to destination.

Why it matters: Represents 40-50% of total logistics costs.

In China-Japan context: Options include ocean freight (cost-effective, 10-15 days), air freight (expensive, 3-4 days), and integrated trucking.

Real example: A furniture importer moving 40 containers from Shanghai to Yokohama relies on ocean freight transportation coordinated with customs brokers at both ports.

Function 2: Warehousing & Storage

Definition: Temporary holding of goods at strategic locations.

Why it matters: Reduces delivery times, enables bulk purchasing, and absorbs demand fluctuations.

In China-Japan context: Regional distribution centers in Tokyo, Osaka, and Fukuoka are strategically positioned to serve Japanese retailers.

Real example: Electronics importers maintain warehouse inventory in Kobe to fulfill rapid retail replenishment orders within 24-48 hours.

Function 3: Inventory Management

Definition: Optimization of stock levels to balance availability with carrying costs.

Why it matters: Excessive inventory ties up capital; insufficient inventory causes stockouts.

Modern approach: Real-time visibility systems (WMS), demand forecasting, and just-in-time (JIT) delivery.

Real example: Fast-fashion retailers coordinate inventory levels to push seasonal collections into Japanese distribution centers exactly when retailers need them.

Function 4: Packaging & Handling (Palletization)

Definition: Preparation of goods for transport, protecting quality while optimizing space.

Why it matters: Reduces damage rates from 3-5% to <0.5% and improves warehouse efficiency.

検討する: Eco-friendly packaging, standardized pallet configurations, and hazmat compliance.

Real example: Auto parts suppliers package components on standardized pallets that fit exactly within 40-foot containers, maximizing space utilization.

Function 5: Order Fulfillment & Distribution

Definition: Processing customer orders and delivering them to the final destination.

Why it matters: Directly impacts customer satisfaction and return rates.

Modern methods: Pick-and-pack operations, cross-docking, and value-added services (like kitting or labeling).

Function 6: Information Management

Definition: Real-time tracking, documentation, and communication across the supply chain.

Why it matters: Provides visibility, enables problem-solving, and supports customs compliance.

Technologies: IoT tracking, blockchain for documentation, and API integration with customer systems.

Real example: Importers receive real-time port status, customs clearance notifications, and delivery ETAs through integrated logistics platforms.

3. What is Logistics Management for China-to-Japan Importers?

Logistics management is the orchestration of all six functions mentioned above into one coordinated system. For China-to-Japan trade specifically, logistics management involves:

Strategic Planning

Demand forecasting for seasonal peaks (e.g., before Golden Week, Christmas, Back-to-School periods).

Network design to optimize cost and service levels.

Carrier selection and contract negotiation.

Technology infrastructure investment.

Tactical Execution

Daily shipment coordination.

Customs documentation management.

Cost monitoring and variance analysis.

Problem-solving when disruptions occur.

Continuous Optimization

Performance measurement (delivery on-time rate, damage rate, cost per unit).

Process improvements through data analysis.

Supplier and carrier performance review.

The Modern Logistics Landscape: What is 3PL?

Given the complexity of China-Japan trade logistics, many companies outsource to 3PL (Third-Party Logistics) providers—companies specializing in warehousing, transportation, and fulfillment. A 3PL manages the entire operation, freeing the importer to focus on product development and sales.

Benefits of 3PL logistics:

Eliminates the need to build an in-house logistics team.

Provides scalability during demand peaks.

Offers expertise in customs clearance and regulatory compliance.

Reduces fixed capital investment in warehouses and equipment.

Cost Savings Through Optimized Logistics: Companies using professional logistics management for China-to-Japan operations report:

15-20% reduction in shipping costs through consolidation.

30% faster inventory turns through optimized warehousing.

90% reduction in customs delays through expert documentation.

25% lower damage rates through improved handling.

If you want to know more about 3PL, you can read:

The Complete Guide to 3rd Party Logistics Services: Transforming Global Supply Chains in 2025

Third-party logistics have brought a major change to how companies manage their logistics and supply chains. Businesses that use logistics outsourcing providers can achieve better results, cut their costs, please their customers and easily adjust to new market situations. Companies like GWT Worldwide cover all areas of logistics such as

Third-Party Logistics Company: Complete Guide to 3PL Services

The third-party logistic firms also offer vital outsourced solutions such as warehousing, transportation, inventory management, and order fulfilment. The main benefits irrespective of the cost reduction offered by these specialized providers are the availability of advanced technology, scalability, and worldwide presence. Publications are intended to discuss some of the criteria

サードパーティロジスティクスのトップ企業2025年の主要3PLプロバイダー究極ガイド

It is a definitive guide covering the top third-party logistics firms and the things a business should consider when looking to partner with logistics providers. Whether it is a large, established global industry player such as DHL Supply Chain and Kuehne + Nagel or a niche player serving a particular

For any questions, feel free to GWT Shippingまでお問い合わせください。 当社チームが、お客様の具体的なニーズに合わせて、専門的かつ国際基準に準拠したアドバイスをご提供いたします。

4. Why Does Logistics Matter for Your China-Japan Supply Chain?

In increasingly competitive markets, what is logistics isn’t just a definitional question—it’s a competitive necessity. Superior logistics capabilities directly influence:

Speed-to-Market: Products arriving 2-3 days faster than competitors can achieve higher retail placement and seasonal sales.

Cost Management: Optimized logistics reduces total supply chain costs by 15-25%, directly improving profit margins.

Customer Satisfaction: On-time, damage-free delivery creates loyal retail partners and repeat business.

Risk Management: Professional logistics provides insurance, security, and compliance expertise that protects your business.

Scalability: As your China-Japan import volumes grow, professional logistics infrastructure scales without proportional cost increases.

Real-World Logistics Success in China-Japan Trade

Case Example 1: Electronics Importer

Challenge: Inventory sitting in Shanghai ports due to customs delays.

Solution: Engaged a 3PL with customs expertise; reduced clearance time from 5 days to 1 day.

結果: 40% reduction in working capital tied up in transit inventory.

Case Example 2: Textile & Apparel Retailer

Challenge: Seasonal demand required 200 containers in August but only 20 in December.

Solution: Implemented flexible warehousing through a 3PL; paid for storage only when needed.

結果: 35% cost reduction during off-season periods.

Case Example 3: Automotive Supplier

Challenge: Just-in-time delivery requirement of ±12 hours to a Japanese factory.

Solution: Positioned safety stock in a regional warehouse; enabled daily, pull-driven replenishment.

結果: Zero stockouts, improving manufacturing efficiency at the customer’s plant.

5. How to Optimize Logistics from China to Japan

Five strategies for superior logistics performance:

1. Partner with Specialized 3PL Providers Instead of attempting to manage complex China-Japan logistics internally, work with experienced 3PL companies that have established relationships with:

Major Chinese ports (Shanghai, Shenzhen, Ningbo)

Japanese ports (Yokohama, Kobe, Nagoya)

Customs brokers in both countries

Regional distribution centers throughout Japan

2. Implement Visibility Technology Modern logistics relies on real-time information. Demand features such as:

GPS tracking of shipments

Port status notifications

Customs clearance alerts

Warehouse inventory visibility

3. Consolidate Shipments Instead of shipping partial containers (LCL), consolidate multiple purchase orders into full container loads (FCL). This reduces per-unit freight costs by 30-40%.

4. Optimize Inventory Positioning Strategically position inventory in Japanese distribution centers to serve regional demand:

Central Japan distribution center (Nagoya) serves Toyota suppliers.

Kobe/Osaka centers serve Kansai region retailers.

Tokyo centers serve the Kanto region market.

5. Implement Demand Forecasting Use historical sales data and retail point-of-sale information to forecast demand accurately, reducing both excess inventory and stockouts.

結論

To summarize: What is logistics? It is the strategic management of the complete flow of goods, information, and resources from China through Japan’s supply chain. It encompasses transportation, warehousing, inventory management, packaging, order fulfillment, and information systems—all coordinated to achieve speed, cost-effectiveness, and reliability.

For companies importing from China to Japan, logistics is not a support function—it is a core competitive advantage. Whether you manage logistics internally or partner with a 3PL provider, understanding what logistics means and how its six functions interconnect is essential to supply chain success.

The most successful importers recognize that what logistics is in their business is fundamentally about moving products efficiently while managing costs and maintaining quality. By optimizing logistics operations, you directly improve profitability, accelerate growth, and build a sustainable competitive advantage in the dynamic China-Japan trade environment.

Key Takeaways:

Logistics encompasses six interconnected functions beyond simple transportation.

Professional logistics management reduces costs by 15-25% and improves delivery times by 2-3 days.

3PL partnerships provide expertise, scalability, and risk management.

Real-time visibility and demand forecasting drive operational excellence.

Strategic logistics capabilities determine competitive success in China-Japan trade.

FAQ(よくある質問)

This is one of the most common sources of confusion. While the terms are related, they have distinct meanings:

Supply Chain Management (SCM) is the broader discipline that encompasses the entire network of organizations, resources, and activities involved in creating and delivering products. SCM includes strategy, procurement, manufacturing decisions, sales, and returns management.

Logistics, by contrast, focuses specifically on the physical movement and storage of goods. Logistics is essentially the operational execution arm of supply chain management.

Think of it this way: SCM is the complete system; logistics is the transportation and warehousing component within that system. For China-Japan importers, SCM strategy might involve deciding to manufacture in China and sell in Japan. Logistics is the detailed execution of moving those products reliably and cost-effectively from Chinese factories to Japanese retailers.

Understanding these distinctions is critical for importers:

3PL (Third-Party Logistics) providers manage specific logistics functions: warehousing, transportation, and fulfillment. They execute your logistics plan but don’t design it. For China-Japan trade, a 3PL handles port coordination, customs clearance, warehousing in Japan, and last-mile delivery.

4PL (Fourth-Party Logistics) providers are logistics system integrators. They design your entire supply chain network, select and manage 3PL providers, optimize inventory positioning, and continuously improve operations. They function as your “chief logistics officer.”

Recommendation for China-Japan importers:

Choose 3PL if: You have experienced internal logistics management and want to outsource execution.

Choose 4PL if: You lack internal logistics expertise and want comprehensive supply chain optimization.

A typical China-to-Japan shipment includes these cost components. Note that rates are volatile and depend on season and carrier.

| 費用項目 | Percentage of Total | Amount (per 40ft container) |

| 海上輸送 | 35-45% | $450 – $800 |

| Port Fees (China) | 5-8% | $60 – $120 |

| Port Fees (Japan) | 8-12% | $100 – $200 |

| 通関 | 2-5% | $30 – $80 |

| Inland Transport (Japan) | 15-20% | $200 – $400 |

| Insurance | 1-2% | $20 – $40 |

| Warehousing (per month) | 5-10% | $100 – $300 |

| Total (Est.) | 100% | $960 – $1,940 |

Professional logistics management can reduce these costs 15-25% through negotiated freight rates, optimized port operations, efficient customs clearance, and demand-driven inventory positioning.

The end-to-end logistics timeline from a China factory to a Japanese warehouse is:

Production & pickup in China: 3-5 days

Port loading & documentation: 2-3 days

Ocean transit (e.g., Shanghai to Yokohama): 10-12 days

Port clearance & unloading: 1-3 days

Inland transport (Japan): 2-5 days (depending on destination)

Warehouse receiving & processing: 1-2 days

Total average: 20-30 days

Peak season surges (July-September) can add 5-10 days. Using air freight reduces the total timeline to 7-10 days but increases costs 6-8x.

Customs clearance is a critical logistics function often overlooked by inexperienced importers. It involves:

Documentation preparation: Commercial invoices, bills of lading, packing lists, certificates of origin, and product technical certifications.

Tariff classification: Correctly classifying products under HS (Harmonized System) codes to determine applicable duties.

Duty calculation: Computing import duties, taxes, and fees.

Regulatory compliance: Ensuring products meet Japanese safety, labeling, and environmental standards (e.g., PSE, JIS).

Customs broker coordination: Professional brokers in Shanghai and Yokohama expedite clearance and resolve issues.

A single documentation error can delay clearance by 3-5 days and cost $500-$2,000 in penalties. Professional logistics providers prevent 95% of customs issues through meticulous documentation.

Modern logistics increasingly relies on technology:

Warehouse Management Systems (WMS): Real-time inventory visibility, automated picking/packing.

Transportation Management Systems (TMS): Route optimization, carrier management, and real-time tracking.

IoT & GPS Tracking: Container-level tracking providing real-time location and condition (e.g., temperature) monitoring.

Blockchain Documentation: Immutable digital documentation reducing customs clearance time 30-50%.

Demand Forecasting AI: Machine learning algorithms predicting demand with 85-90% accuracy, optimizing inventory levels.

Automated Port Equipment: Container handling robots reducing port dwell time.

Five proven cost-reduction strategies:

Consolidate shipments: Combine multiple POs into full container loads (reduces freight cost 30-40%).

Optimize inventory positioning: Position safety stock in regional Japanese warehouses (reduces rush shipments 40-60%).

Implement demand forecasting: Reduce excess inventory by 20-30% through accurate demand prediction.

Negotiate volume contracts: Lock in freight rates for 6-12 month commitments (typically a 10-15% discount).

Partner with asset-light 3PLs: Use non-asset-based providers who can flexibly choose the best carriers, often reducing markup.

Essential logistics KPIs (Key Performance Indicators) for China-Japan importers:

On-time delivery: Target >98% (measures delivery performance against commitments).

Damage rate: Target <0.5% (measures product condition upon arrival).

Customs clearance time: Target <2 days average (measures brokerage efficiency).

Cost per unit: Target -5% YoY improvement (measures cost management).

Inventory turnover: Target 6-8x annually (measures working capital efficiency).

Perfect order rate: Target >95% (measures order accuracy and fulfillment quality).

Ready to start your China-Japan shipping?

Thank you for reading!

Have questions, corrections, or better ideas? We’d love to hear from you!

We value every piece of feedback and promise to reply within 24 hours. Let's make this guide better together!

Note: Spam comments will not be published.