How Oversized HVAC Units Passed Pre-Loading Approval on the First Attempt (Wuxi–Brunei)?

1. Project Snapshot

- Service Type: Sea Export (Project Cargo / OOG)

- Equipment: 40′ Flat Rack (40FR)

- Cargo: Industrial HVAC Units (Wheeled, Over-width, Over-height)

- Route: Wuxi (Origin) via Shanghai Yangshan Port (POL) → Muara Port, Brunei (POD)

- Timeline: Fixed / Time-Critical

(Three oversized HVAC units loaded on a 40′ Flat Rack container, featuring white shrink-wrap protection for ocean transit.)

2. Case Background

In December 2025, a Singapore-based client engaged GWT to support an urgent export of three industrial HVAC units from Wuxi, China, to Muara Port, Brunei.

The client had no prior experience with OOG or Flat Rack shipments and lacked internal capability to manage container selection, regulatory compliance, and port-side coordination for oversized cargo.

With a highly compressed delivery schedule and no margin for trial-and-error, the client conducted multiple comparisons among logistics providers before selecting GWT, based on our proven track record in special equipment and project cargo handling.

Once appointed, GWT quickly engaged with the client, reviewed the shipment requirements, and carried out an on-site assessment.

3. Key Challenges

Following the on-site assessment, GWT confirmed that the HVAC units were oversized, over-width and over-height OOG cargo.

Drawing on extensive hands-on experience in Flat Rack and OOG operations, and considering the specific characteristics of this shipment, GWT identified three critical risk areas directly impacting transport safety, regulatory compliance, and delivery schedule:

Stability Risks (Oversized Dimensions)

The units exceeded standard container limitations and required transportation on 40-foot Flat Rack (40FR) containers.

This introduced specific technical risks related to:

- Customized stowage planning

- Accurate center-of-gravity control

- Load stability throughout ocean transit

- Compliance with pre-loading safety approval requirements

Any deviation in load distribution or securing design could increase the risk of cargo damage or approval rejection.

(Customized steel support frames isolate the wheels from the floor, combined with wooden chocks to prevent longitudinal movement.)

The Yangshan Model Bottleneck

The shipment was subject to dual pre-loading approval by both the carrier (MSK) and Shanghai Yangshan terminal.

At the same time, Yangshan operates under a “gate-in before customs declaration” model, significantly compressing the available operational window between:Container gate-in

- Pre-loading approval

- Customs declaration and release

This required precise coordination across documentation, timing, and on-site execution to avoid missed cut-off or rework.

Zero-Tolerance Compliance Standards

Both MSK and Yangshan terminal impose detailed and non-negotiable technical standards for Flat Rack cargo securing (see Technical Appendix).

Any non-compliance, including materials, angles, or securing methods, could result in:Approval rejection

- Terminal gate-in refusal

- Vessel loading denial

Strict adherence to all technical specifications was therefore mandatory to prevent delays and additional costs.

4. Our Solution & Execution

In response to the challenges identified, our team aligned closely with the client’s core priorities: cargo safety, operational stability, and on-time delivery.

We implemented a closed-loop solution covering pre-shipment planning, on-site execution, and post-operation control, ensuring each step was executed with precision and accountability.

(1) Pre-Shipment Engineering

- Accurate container selection

Based on the cargo dimensions and weight profile, a 40-foot Flat Rack container (40FR) was selected to meet the load-bearing and clearance requirements of the oversized equipment, mitigating loading risks at the source.

- Advance allocation of specialized resources

A trucking fleet experienced in special equipment transport and a certified lashing team were mobilized in advance, ensuring all handling and securing activities complied with applicable safety and industry standards.

- Multi-party coordination

Regular coordination was maintained with the Wuxi factory to confirm stuffing schedules.

We supported the factory in arranging lifting equipment and labor in advance, enabling a one-time, efficient loading operation and preserving buffer time for subsequent stages.

(2) Loading & Securing (The Technical Standard)

- Controlled Flat Rack loading procedures

On-site operations strictly followed Flat Rack loading guidelines, with balanced weight distribution, centered gravity, and a minimum 20 cm clearance at the front and rear.

All cargo and lashing materials were kept clear of the container corner castings to ensure safe lifting and transport.

(Visual confirmation of unobstructed corner castings and even weight distribution along the 40′ deck. Note the precise spacing between units to facilitate safe crane lifting.)

- Compliance-focused lashing and securing

- Compliance-focused lashing and securing

Taking into account ocean transit conditions and discharge requirements at destination, cargo was secured in full accordance with carrier standards.

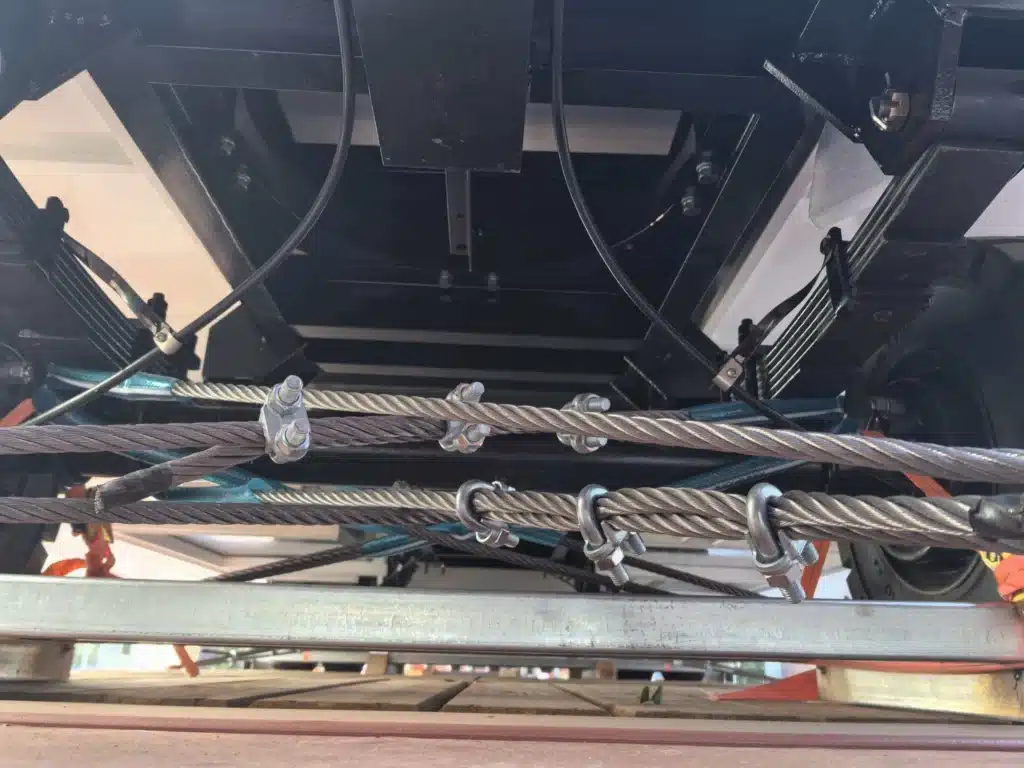

Steel wire ropes of at least 16 mm diameter were used with double-loop turnbuckles (hooks not permitted), with no fewer than three wire clips per rope.

(Steel wire ropes lashed directly to the cargo axles. Note the use of 3 wire clips per strand to meet MSK’s strict safety standards.)

Where lashing belts were applied, only certified products with dedicated locking devices were used; general ratchet tools were strictly excluded.

(Heavy-duty orange lashing belts with dedicated locking buckles used for auxiliary stability. Standard ratchet straps were strictly prohibited.)

- Coordinated inland transportation

- Coordinated inland transportation

Upon completion of loading and securing, the container was transported under full escort by a dedicated Flat Rack trucking team from Wuxi to Shanghai port, ensuring seamless handover to the port operation stage.

(Heavy-duty tarpaulin applied prior to inland transit ensures cargo remains protected from rain and environmental exposure during the journey to Shanghai Port.)

(3) Port & Milestone Control

- Priority management of pre-loading approvals

In line with the “first-come, first-reviewed” policy applied by the carrier (MSK) and Yangshan terminal, a dedicated coordinator monitored port opening times and aligned container arrival and approval submission to secure queue priority. - Advance documentation verification

Given the time-sensitive “gate-in before customs declaration” model at Yangshan, all customs documentation was reviewed and verified with the factory in advance to ensure completeness and data accuracy, reducing clearance risk. - End-to-end milestone monitoring

Key milestones, including empty container pickup, factory loading, approval clearance, port gate-in, customs declaration, release, and vessel departure, were tracked throughout the process.

A rapid response mechanism was maintained to address potential issues in real time, ensuring smooth execution and on-schedule delivery.

5. Project Outcome

Through structured planning and end-to-end operational control, the oversized HVAC shipment from Wuxi to Brunei was completed as scheduled.

All key stages operated smoothly within the planned timeframe. The delivery results are summarized below:

- 100% Audit Pass Rate: Cargo passed both MSK and Terminal inspections on the first submission.

- Zero Rework: No corrective actions or secondary lashings were required at the port.

- Seamless Process: Customs release was achieved within the tight Yangshan operational window.

- Cargo Integrity: Equipment arrived at the destination with zero displacement or damage.

- Cost Avoidance: The client incurred $0 in detention fees, rectification costs, or roll-over penalties.

Key Takeaways for Project Cargo Importers

- Success starts before loading: 80% of OOG failures are due to poor planning, not bad driving.

- Compliance is cheaper than correction: By strictly adhering to carrier standards and conducting pre-shipment technical audits, we effectively eliminated the “hidden costs” of terminal rejection, detention fees, and vessel roll-overs for the client.

- For OOG clients, value lies in Accountability: GWT leverages deep engineering expertise to manage compliance, safety, and port execution. You focus on your core business; we take full responsibility for the technical results.

For Project Cargo clients, true value isn’t about understanding every lashing angle. It’s about knowing who is accountable for the final result.

At GWT, we don’t just sell freight; we sell Result Certainty. Based on decades of OOG experience, we engineer compliant, safe, and efficient solutions that shield you from technical risks.

You Focus on Your Business: No need to micromanage lashing details or port milestones.

We Focus on the Risk: We take full ownership of the technical execution from factory to vessel.

Reference standards adhered to in this project:

- Corner Castings: Must remain completely unobstructed to facilitate crane operations.

- Weight Distribution: Center of Gravity (COG) must be centered longitudinally and transversely.

- Header Clearance: Minimum 20cm distance between cargo and container headers.

- Wire Rope: Min. diameter 16mm, double-strand with closed turnbuckles. (Open hooks prohibited).

- Clips: Minimum 3 wire clips per strand.

- Straps: Certified heavy-duty belts only; standard ratchets are prohibited for heavy OOG.

Founded in 2004, Shenzhen Guanwutong International Freight Forwarding Co., Ltd. (GWT) is a WCA- and AEO-certified global logistics provider offering end-to-end air, ocean, rail, express, and DDP solutions.

With bonded warehouses in Shenzhen, Dongguan, and Fuzhou, plus 24/7 customs brokerage and real-time tracking, we deliver reliable, compliant, and tailored freight services to 3000+ clients across 190+ countries.

Have a complex shipment? Let us handle the engineering.

Thank you for reading!

Have questions, corrections, or better ideas? We’d love to hear from you!

We value every piece of feedback and promise to reply within 24 hours. Let's make this guide better together!

Note: Spam comments will not be published.