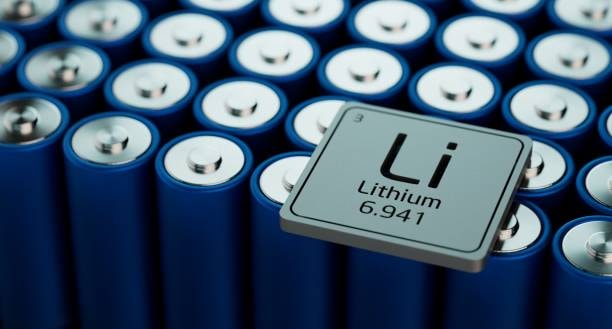

Lithium ion batteries provide power to different devices, including smartphones, computers, electric cars and storage systems. Since demand for fuel like natural gas is rising worldwide, it has become very important for manufacturers, distributors and logistics providers to understand all aspects of shipping these powerful energy sources. This thorough guide looks into lithium ion battery shipping, outlining regulations, safe methods and industry concerns that allow for proper shipments across countries.

Understanding Lithium Ion Battery Classifications

The initial step in safe shipping of lithium ion batteries is correct classification. IATA and IMO have provided special guidelines about the way these batteries must be handled, labeled and handled during shipping, which outline specific shipping restrictions . If shipped alone, lithium ion batteries are listed as UN3480 and when packed with equipment or in equipment, their listing is UN3481.

It is necessary to recognize these classifications since every category has specific requirements for packaging, limited quantities and paperwork demands. UN3480 batteries need to be packed in the tightest way and are normally restricted to shipment by cargo aircraft only. Batteries in UN3481, specifically lithium ion batteries packed with equipment, are allowed some deviations in the requirements yet they still require proper packaging and labels. At the same time, batteries in equipment that comply with UN3481 usually have relaxed rules, nonetheless, safety is always a priority.

How many watt-hours the rated capacity of battery can provide also needs to be determined as it affects the methods and rules needed for shipping. Packages or items that have batteries with more than 100 watt-hours for lithium ion cells or 300 watt-hours for lithium ion battery assemblies may not be allowed and special actions or permits may be needed for shipment.

International Shipping Regulations and Compliance

You have to be familiar with several international shipping rules to manage lithium ion batteries properly. Regarding air travel, cargo that could be dangerous is handled according to the IATA Dangerous Goods Regulations and the IMDG Code regulates such shipments for sea freight. These agreements such as the ADR in Europe and similar regulations elsewhere, help govern land transport of dangerous goods.

Regulatory bodies establish particular rules for filing documentation, preparing packages, labeling products and dealing with them. The rules set by IATA are strict and they are updated regularly with changes linked to new safety issues and technological progress. Lately, there have been updates that involve better packaging, different limits on shipping items and tougher testing for lithium batteries.

Compliance requires following rules and also providing training for employees, detailed record-keeping of shipments and using quality assurance methods. Every organization should put in place a good compliance system that monitors changes in regulations, guarantees proper certification of workers and keeps records of every lithium battery shipment.

When shipments do not meet the rules, dangerous events can occur and businesses may have to deal with big penalties, delayed shipments and legal action. For that reason, companies transporting lithium ion batteries across borders rely heavily on experienced logistics companies that handle shipping dangerous goods.

Packaging Requirements and Standards

The key to safe transportation of lithium ion batteries is proper packaging. The United Nations has created rules that packaging must meet for every type of battery. They are called Packing Instructions and they provide clear details about packing inside the box, outside the box, the use of packaging cushions and safety measures.

Packaging for lithium ion batteries (UN3480) should meet UN requirements and pass tough tests to make sure it remains intact while being moved. These tests cover drop tests, vibration tests and stack tests that represent the way lithium cells and other products are shipped in real life. The container must include enough soft padding to avoid harm to the battery as it moves while being shipped.

There are extra risks when batteries are included with other equipment (UN3481). It is important to secure the equipment so it will not be activated during transport and the entire packaging should be made to defend the lithium ion batteries contained and the related equipment from damage. Often such shipments need tailored packaging to suit the needs of the equipment that is being shipped.

Usually, equipment that holds batteries (UN3481) can be handled in the most convenient packaging since the equipment itself is the main shield for the batteries. But, all the equipment and batteries contained should be secured within the container and such requirements as labeling and paperwork still need to be met.

All packaging used for mobile phones should have safety cushioning which is non-conductive as well as protective. Certain cushioning substances should be chosen mindfully to ensure they do not harm lithium batteries and still maintain their safety features during shipping.

Air Transport Specific Guidelines

Unique factors in air transport, including the fluctuating flight altitude, temperature and little access while flying, make it hard to deal properly with lithium ion batteries. Air transport of hazardous materials is guided by the IATA Dangerous Goods Regulations which are typically more strict than regulations used elsewhere.

It is very important to understand the rules for passenger aircraft. Shipping lithium batteries with higher watt-hours or large amounts is almost always limited to cargo aircraft. They are made because of worries that fires might start in passenger areas and that the crew cannot control them efficiently from the flight deck.

The allowable number of batteries on flights is set and it depends on the type of battery, its capacity and the kind of aircraft. Shippers have to determine the total lithium content or watt-hour rating of the shipment by regulation. Any shipment that goes past these limits may be turned down, delayed for a costly period or found guilty of penalties.

It is common for air transport regulations to ask that batteries have protective measures, for example using insulating tape or separate packaging, just in case there is a short circuit. Batteries should be kept safe from other cargo which means that loading them needs to follow certain rules and cargo separation guidelines.

There needs to be clear information about batteries, their names and how dangerous they are for air transport. While handling dangerous goods, you should add appropriate notes and declarations to your air waybills and all employees dealing with such shipments must be trained and certified.

Sea Freight Transportation Considerations

Shipping lithium ion batteries by sea is a possible option because the rules are more flexible than those for air transport. The IMDG Code is designed for sea shipping and sets out guidelines for packing, putting containers on ships and maintaining separation of goods aboard vessels.

Sizeable shipping boxes are placed with care, not together with unmatched materials and proper ventilation is provided. Lithium batteries should be stored in a place that offers sufficient airflow and protection from extreme cold or heat and where they are kept aside from any goods that might react with them.

Since sea freight does not reach its destination quickly, controlling the temperature is vital to avoid problems from the weather. Batteries may need to be monitored by temperature sensors or adjusted using climate control devices to avoid temperature risks during the transportation process.

A Dangerous Goods Declaration must be provided when shipping lithium batteries and needs to cover all information related to their risks. The statement is put in the ship’s manifest and is used by people at the port and emergency personnel to determine what is on the vessel.

Because of factors such as limited fire support and access to cargo, special care must be taken when putting together emergency procedures for sea transport. Everyone on board needs to be ready for emergency situations with lithium batteries and all information about who to contact must be close at hand.

Land Transport Protocols

Land transport regulations for lithium ion batteries vary according to the area and the way they are being transmitted. On roads across Europe, the ADR regulations are applied and other areas and forms of transport such as rail, have their own similar rules.

For land transport, some vehicles used for transporting dangerous goods must have emergency equipment, fire extinguishers and helpful communication tools. All those transporting lithium batteries ought to have dangerous goods endorsements and receive regular training on this type of shipment.

Things to consider when planning a route are limits on certain roads or tunnels, needed rest stops and rules about traveling during set hours. They are introduced to lower risks and guarantee suitable emergency action throughout the transportation area.

Packages should be carefully loaded and unloaded to guarantee there is no damage and the battery is handled safely along the way. Appropriate equipment should be used for handling these materials and only trained staff who know the dangers of lithium batteries should do the loading and unloading.

Land transport documentation consists of shipping documents, information about dealing with emergencies and authoritative contact details. It is required for drivers to have all these documents on hand at all times and be ready to provide them whenever needed by officers.

Safety Protocols and Risk Management

Strong safety procedures must be put in place to control the risks of shipping lithium ion batteries. They have to deal with possible dangers such as thermal runaway, fire, lithium metal gas poisoning by chemicals and electrical hazards that might take place during transit.

The procedures for analyzing risks should consider possible ways that things may fail, the conditions in the environment and any issues related to people making mistakes. The assessment should check the entire process, starting from placing items in a box up to their last delivery, to find important places where further action may be required.

For emergency response planning to be effective, shippers, carriers and emergency responders have to join efforts to ensure sufficient resources and skills are on hand in case of incidents. Response plans need to handle cases such as package damage, battery fire and dangerous gas release by setting out specific actions for each situation.

According to the lithium battery shipping regulations, anyone handling the shipping of lithium batteries must learn about hazards, the necessary procedures, what to do in case of accident and the rules involved. Refresher courses make certain workers always know the latest rules and standards.

Systems for quality assurance should supervise how safety rules are followed, check incident reports and carry out ongoing progress improvements. They assist in noticing any issues in the system and make sure safety procedures never die out.

Documentation and Labeling Requirements

Shipping lithium ion batteries requires correct documentation and proper labels since they ensure the process is in line with regulations and inform everyone involved. For every type of transport and wherever you are going, you will need to use certain forms and signatures included in the package.

Battery specifications in a dangerous goods declaration should mention the UN codes, approved names, divided-into-groups and the classes each section falls under. Declarations are the main way for shippers to tell carriers what matters for a safe and proper delivery.

Shipping labels and markings have to be designed within specific requirements for size, color, location and details they carry. The IATA lithium battery mark is put on packages to immediately show the contents and include information to call in the event of problems while transporting the batteries.

Standard battery specification documents should explain capacity, voltage, how the battery is built and its safety features. It is important information for emergency personnel, who should know about the unique characteristics of the batteries when an incident occurs.

You may need to offer tests that prove you meet UN rules for packaging, agreements from the manufacturer certifying compliance and certificates verifying the quality of your goods. They indicate that the batteries and their packaging conform with required safety standards.

Proper tracking is made possible with chain of custody paperwork which ensures supplies are handled and shipped safely battery manufacturers. It serves as important evidence when handling incidents or showing that you follow the regulations.

Cost Considerations and Budgeting

Besides the freight cost, shipping lithium ion batteries requires special packing, necessary documents, insurance and expenses to comply with regulations. Only by understanding these costs can you make correct budgeting and pricing choices damaged lithium batteries.

The packaging needed for air transportation can be very expensive, as it must be UN approved and well cushioned li ion batteries. The price for these batteries depends on how big they are, how many are needed and where they are shipped, with custom packaging usually meaning a higher charge rechargeable batteries.

Lithium batteries are usually more expensive to ship because they require special care, have strict volume limits and call for more insurance. Some carriers require additional fees for handling hazardous goods, preparing paperwork and checking if guidance is complied with.

Issues to be covered by insurance are the batteries, problems with shipping that may result in accidents and disruptions caused by scheduling issues or bans on shipping. It is common for general cargo insurance not to be sufficient, as lithium batteries require dedicated insurance meant for dangerous goods.

Ensuring compliance means spending on learning, being certified, preparing written materials and possibly facing fines for breaking the rules. Lithium battery shipping often leads to high expenses, mainly for businesses that regularly or frequently transport them lithium batteries pose.

For example, storage fees can be incurred when shipments are held up, repackaging needs to be done if the package is wrongly prepared and there are lost business opportunities since you cannot deliver the goods on time. Proper organization and partnering with experts can reduce the number of these hidden costs international air transport association.

Technology and Innovation in Battery Shipping

Recent improvements in technology are making it possible to safely, accurately and efficiently ship lithium ion batteries. They are meant to lower the chances of issues as well as improve efficiency and keep costs down.

Using sensors, smart packaging can check the temperature, humidity and shock sensitive areas as it moves from one place to another. As a result of this real-time monitoring, experts can fast-act if the environment is not well controlled and use the gathered information to improve shipping processes.

With such systems, both senders and receivers of goods can monitor the movement, state and expected arrival time of shipments. Using advanced technology, people involved can be notified instantly about delays or problems, so they can act fast to reduce their effects spare batteries.

Innovators have created systems that are especially for lithium battery fires and work to put out electrical fires by lessening damage to what is nearby. Some of these systems can be built into packing or shipping containers to increase safety.

The purpose of packaging material progress is to make lightweight, tough and affordable materials that comply with rules and lower the cost of shipping products, including lithium metal batteries . Some of the new materials can cover a greater range of thermal, shock or fire risks standalone lithium ion batteries.

Using electronic documentation for shipping speeds up the process and ensures fewer mistakes and better follow of rules. Such systems can make needed forms, monitor new regulations and record everything for compliance lithium cell.

Environmental Impact and Sustainability

The environment can be affected by lithium ion batteries shipping during transportation, in their packaging materials, by the use of fuel and also at the end of their life span. As people pay more attention to the environment, sustainable shipping is gaining importance.

Companies concentrate on producing reusable packaging, adjust the size of their packages to use less material and identify materials that are friendlier to the environment. They may lower the negative effect on nature from shipping batteries and also cut shipping expenses.

One needs to pay attention to carbon footprint when deciding on types of transport, making packaging and waste management. Taking products across the sea can result in lower carbon emission levels, however, it takes a longer journey than air travel.

It is important that recycling and disposal follow rules for both the batteries and the material used to ship them. Correct end-of-life actions let us safely recover significant resources and prevent any pollution.

Companies can make logistics more sustainable by taking shorter routes, combining different consignments and picking suppliers who are friendly to the environment. These techniques help achieve sustainability objectives and usually lead to financial savings.

Xu hướng tương lai và sự phát triển của ngành

The battery shipping industry keeps growing due to new technologies, changes in regulations and what the market wants. For organizations that want to plan shipping well into the future, it is vital to know about such trends.

There is steady development in regulation as experts balance the need to protect with the need to operate ships efficiently. Regulations in the future might involve stricter testing, packaging that meets updated standards or complete documentation because of experience and technological progress in the industry.

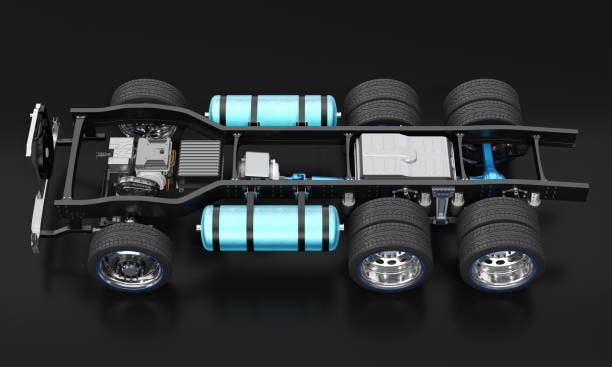

It is expected that demand for lithium batteries will keep increasing because of rising electric vehicle use, more renewable energy storage and progress in consumer electronics. Such an increase will probably use up current shipping capacity and lead to new developments in transportation systems.

Changes in technology are seen in automating packaging and documentation, better monitoring and tracking and the creation of custom ways to transport lithium battery shipments.

Industry consolidation might have logistics service providers caring for more dangerous goods which may raise the overall quality of service and cut back on competitors. As a result, the cost and the availability of services could change for companies that transport batteries.

Phần kết luận

Skill, diligence and focus on ongoing development are needed to ship lithium ion batteries safely and in accordance with rules. In a quickly developing logistics sector, using the services of GWT Worldwide ensures your batteries are protected and delivered safely, all while controlling any associated risks and saving money. In the coming years, shipping lithium batteries will most likely require more regulations, better technology and more attention to sustainable practices, so those who work in this field must continue learning and adjusting to the changes.

Thank you for reading!

Have questions, corrections, or better ideas? We’d love to hear from you!

We value every piece of feedback and promise to reply within 24 hours. Let's make this guide better together!

Note: Spam comments will not be published.