Typhoon Risk Management for Freight Forwarding

By Guanwutong / October 16, 2025

Recently, Typhoon No. 23, also known as Typhoon Nakri, passed over Japan, bringing strong localized winds and high waves, particularly impacting the Izu Islands and parts of the Kanto region.

Despite these conditions, major ports remained fully operational, reflecting effective preparedness and the storm’s moderate intensity.

This event is part of a wider pattern of frequent tropical cyclones in East and Southeast Asia. In recent weeks, Typhoon Ragasa caused significant damage in China and the Philippines. Meanwhile, Haishen and Noru have affected Japan, Korea, the Philippines, and Vietnam.

The combined effect of warm sea surface temperatures in the Western North Pacific Ocean and the South China Sea, alongside subtropical high-pressure systems and prevailing monsoon winds, creates ideal conditions that steer these storms toward key coastal hubs.

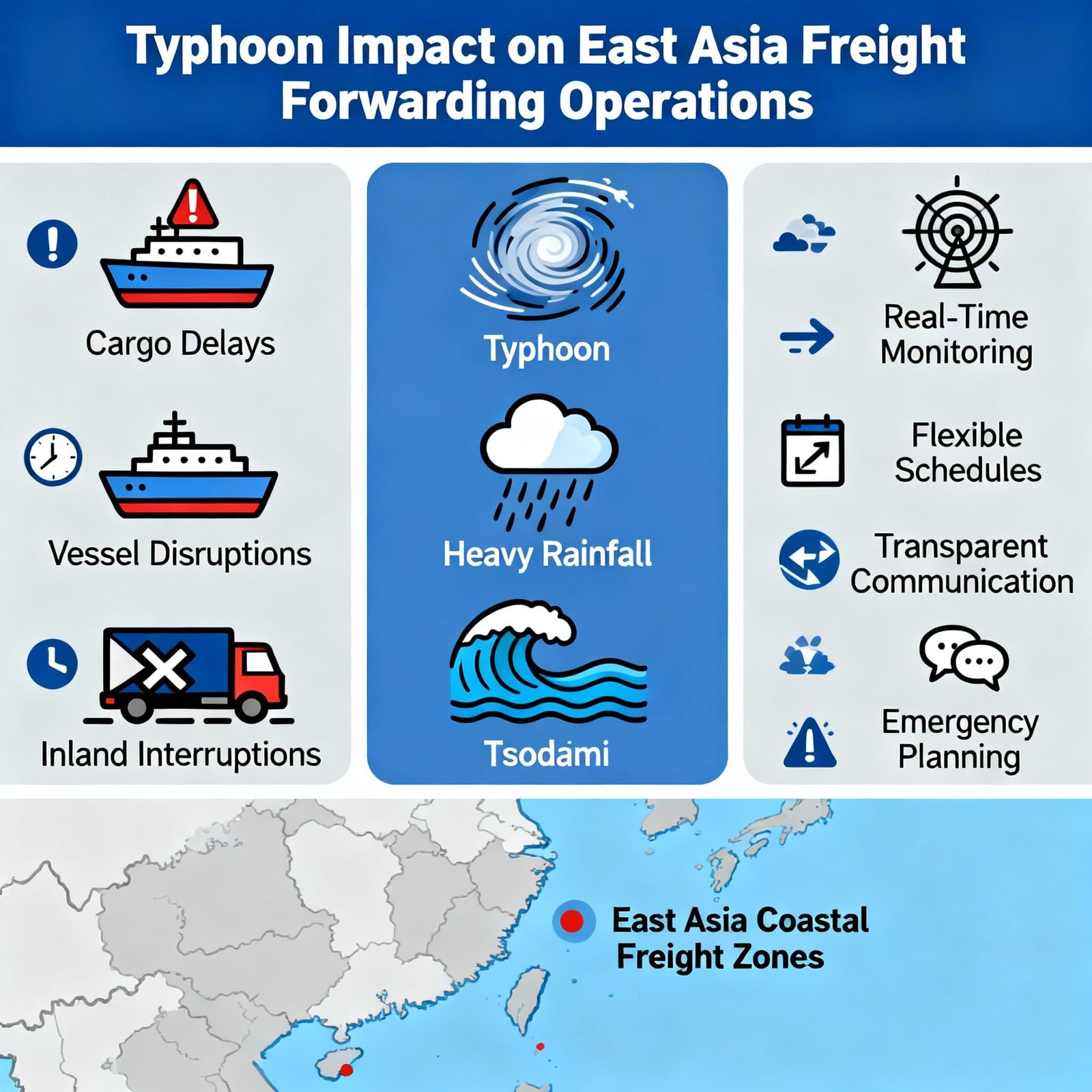

For freight forwarders, these typhoons and related hazards, such as tsunamis, heavy rainfall, and flooding, pose ongoing operational challenges.

Typical impacts include cargo handling delays, vessel schedule disruptions, and interruptions to inland transportation networks.

Proactive strategies like real-time weather monitoring, flexible shipping schedules, transparent client communication, and rapid emergency response plannin, are essential to maintain logistics risk management, minimize shipping delays, and strengthen client trust.

By understanding these weather patterns and their operational impacts, freight forwarding companies can anticipate risks, optimize shipping routes and schedules, and maintain reliable service even amid East Asia’s volatile typhoon seasons.

The Impact of Typhoons on Global Trade and Freight Operations

1. Shipping Delays and Port Congestion During Typhoon Events

Typhoons significantly disrupt maritime shipping and port operations. Vessels often seek shelter or leave port earlier than planned, resulting in delays typically ranging from 3 to 7 days.

These disruptions affect the entire supply chain’s scheduling and delivery rhythm. Port congestion intensifies the issue, as ships wait offshore, causing container backlogs and overwhelming cargo yards. These constraints lead to higher sea freight rates due to reduced operational capacity.

For instance, during Typhoon Co-May in 2025, major ports like Shanghai and Ningbo temporarily closed, causing shipment delays of up to a week and backing up over 1 million TEUs in the Yangtze River Delta. It reflect recurring challenges in typhoon-prone regions globally, highlighting the need for resilient logistics strategies.

2. Port Operation Interruptions and Equipment Downtime

In response to typhoons, many ports close partially or completely for 2–3 days, drastically reducing throughput.

Key ports in Eastern and Southern China, Southeast Asia, and Japan face suspended loading/unloading activities and equipment downtime.

Workforce safety restrictions also contribute to slower container turnover.

Time-sensitive cross-border e-commerce shipments and high-priority parcels experience disproportionate delays due to these limitations.

3. Inland Transportation and Delivery Risks

Typhoon-driven flooding, landslides, and infrastructure damage disrupt roads and railways connecting ports to inland hubs.

These disruptions extend last-mile delivery times regionally.

Truck drivers operate under hazardous conditions, requiring reduced speeds and greater cargo securing efforts.

Cross-border express shipments and small parcel deliveries face significant time delays, requiring clients to build in sufficient buffer times.

4. Legal Considerations and Insurance Risks Amid Typhoon Hazards

Typhoons are often treated as force majeure events, but carriers may still be liable if reasonable preventive steps were not taken.

Freight forwarders and shippers must maintain diligent risk management to reduce liability.

Insurance coverage is critical due to increased risk of cargo water damage and contamination.

Comprehensive marine insurance policies covering seawater ingress and storm-related loss, combined with careful container sealing and packaging, help mitigate financial exposure.

5. Indirect and Broader Supply Chain Impacts

Port closures and shipping delays cause temporary reductions in export volumes at affected hubs.

Customs declaration volumes may hold steadier as backlogs clear post-typhoon.

High freight rates and delayed schedules contribute to budget overruns and require adjusted production and inventory plans.

A post-typhoon surge in cargo clearance can strain port throughput in the short term but also highlights limitations in long-term cargo capacity affecting global trade flows.

What Should Different Departments Do to Prepare and Respond During Typhoon Season?

1. What Should Ship Officers Do Before and During a Typhoon?

Conduct thorough inspections of all deck areas and hatch covers, ensuring all vents, air pipes, deck entrances, and portholes are fully closed and sealed except for emergency exits.

Secure all watertight doors firmly to prevent water ingress during storms.

Check and ensure main engines, auxiliary machinery, and boilers are fully operational throughout the typhoon period to enable emergency maneuvers if needed.

Increase the number of mooring lines and reinforce hatch covers to maintain stability while berthed.

Continuously monitor updated weather reports and be prepared to move the vessel promptly to a safe anchorage or remain secured in port, depending on storm severity.

2. How Should Ports and Terminal Operators Prepare for Typhoon Impacts?

Establish and operate dedicated typhoon monitoring and early warning systems to track wind speeds, storm paths, and sea conditions in real time.

Immobilize cranes, yard gantries, and cargo handling machinery ahead of peak winds using proper anchoring and windproof locking devices.

Manage empty container yards by reducing stack heights and securing containers firmly to prevent damage from strong winds.

Suspend cargo handling operations when wind speeds exceed safety thresholds and coordinate timely vessel evacuation to safe anchorages.

Maintain open, frequent communication between port authorities, shipping lines, and freight forwarders to ensure coordinated responses and consistent operational commands.

3. What Safety and Operational Measures Should Land Transport and Logistics Teams Implement?

Limit or avoid vehicle movement during typhoons to reduce accidents; park vehicles away from flood-prone or structurally hazardous zones such as low-lying areas and temporary shelters.

Enforce safe driving practices including maintaining low speeds, increasing following distances, avoiding sudden braking or sharp turns.

Advise drivers to cross flooded roads slowly and steadily in low gear to maintain traction and safety.

Ensure cargo is tightly secured with lashing and covered with waterproof tarps to protect against rain and water damage.

Monitor road conditions and weather advisories continuously; adjust delivery schedules and reroute as necessary, communicating promptly with clients.

4. What Legal and Insurance Measures Should Organizations Prioritize for Typhoon Seasons?

Clearly define force majeure clauses in contracts to specify responsibilities and liabilities during typhoon disruptions.

Assess the preventive measures taken by carriers and partners to evaluate liability exposure.

Purchase comprehensive marine insurance with coverage for water damage, flooding, and shipment delays specific to typhoon conditions.

Prepare to document and notify insurers quickly upon cargo or vehicle damage to facilitate efficient claim processing and minimize prolonged losses.

Why Partner with GWT Shipping: Reliable Support Through Typhoon Challenges

1. Proactive Weather Monitoring and Flexible Routing

GWT Shipping monitors regional typhoon alerts 24/7 to anticipate weather disruptions early.

We swiftly implement flexible routing, including alternative sea, air, and rail options, to avoid affected ports and minimize delays.

This agile approach ensures your cargo continues moving despite typhoon-related obstacles.

2. Transparent and Patient Client Communication

Our team provides timely, clear shipment status updates during severe weather events.

Clients receive detailed information on potential delays and contingency plans, empowering proactive decision-making.

We maintain constant dialogue to alleviate concerns and build trust during uncertain times.

3. Integrated Customs Brokerage for Efficient Clearance

GWT Shipping integrates customs brokerage with freight forwarding, speeding up cargo clearance.

Even amid weather disruptions, this reduces administrative bottlenecks that could worsen delays.

Our expertise helps avoid unnecessary hold-ups at ports and accelerates deliveries.

4. Strategic Bonded Warehousing and Inventory Buffering

We maintain bonded warehouse facilities across key Chinese logistics hubs.

These facilities enable staging of inventory ahead of forecasted typhoons or secure storage when shipment delays occur.

This strategic buffering mitigates supply chain shocks and smooths post-storm recovery.

5. Strong Partnerships and Local On-Site Support

GWT Shipping’s long-term cooperation with carriers, port authorities, and ground logistics providers ensures prioritized access to vital resources.

Our local teams respond rapidly to evolving conditions, coordinating stevedoring, trucking, and distribution even in constrained environments.

This combined global and local reach maintains supply chain continuity through typhoon seasons.

6. Comprehensive and Specialized Freight Services

We handle vận chuyển đường biển (FCL, LCL), vận chuyển hàng không, express courier shipments, and rail routes efficiently.

GWT Shipping is qualified to transport dangerous goods safely, adhering strictly to international safety and compliance standards.

This service diversity offers suppliers full logistics flexibility despite unpredictable weather.

7. Commitment to Minimizing Risk and Ensuring Reliability

Partnering with GWT Shipping means gaining a dedicated team that proactively manages typhoon impacts.

We focus on minimizing financial loss, preventing inventory shortages, and maintaining your customer satisfaction no matter the weather.

Through steadfast operational excellence, we help your business remain resilient during every storm and calm.

Phần kết luận

During the typhoon season, especially in East Asia, strong tropical cyclones frequently form due to high sea surface temperatures in the Western North Pacific and South China Sea, combined with subtropical high-pressure systems and monsoon winds. These storms often impact coastal ports and transportation networks.

To navigate this high-risk environment, freight and logistics companies must prepare comprehensively. Real-time weather monitoring, flexible routing and scheduling, transparent client communication, and well-designed emergency plans allow companies to effectively manage port closures, vessel delays, and inland transportation risks, ensuring cargo safety and supply chain continuity.

Partnering with experienced logistics partners like GWT Shipping, applying scientific scheduling strategies, and maintaining on-site emergency capabilities help freight forwarders stay resilient during the frequent typhoon season, ensuring reliable, efficient, and stable logistics services.

FAQ: Impact of Typhoons on Shipping and Supply Chains

Typhoons can force vessels to delay departure, reroute to safer paths, or anchor offshore to avoid storm damage. For example, during Super Typhoon Yagi in 2024, significant port closures occurred in Hong Kong, Macau, Guangdong, and Guangxi, leading to shipment delays averaging 6–30 days. Ports often suspend cargo handling and customs operations when wind speeds exceed safety limits, halting supply chain flow temporarily. Inland transport disruptions from flooding or road closures can ripple across the logistics network, further delaying product delivery and creating shortages downstream.

Forwarders monitor real-time weather and sea conditions, maintain communication with shipping lines and port authorities, and proactively adjust routing and schedules. Multiple routing options and flexible warehousing allow quick adaptation. During typhoon Ragasa in 2025, highly agile freight forwarders employed contingency plans that reduced downtime and enabled faster cargo movement once ports reopened, mitigating financial losses and customer dissatisfaction.

Diversifying suppliers and transport routes reduces dependency on vulnerable nodes. Maintaining buffer stock of critical materials provides operational resilience during delays. Early shipment of essential goods before peak typhoon months and close coordination with logistics partners ensures readiness. Apple exemplified this approach during Southeast Asia floods by quickly switching to alternative suppliers and investing in local infrastructure improvements.

Ports suspend operations during extreme winds, preventing accidents but halting cargo flows. Post-typhoon, backlogs lead to congestion in container yards and lengthened vessel berthing queues, as seen in Hong Kong’s historic 36-hour airport closure during Ragasa. Ports implement staged clearance and coordinate closely with inland depots and logistics firms to manage the surge and gradually restore efficiency.

Rerouting shipments around flood-prone routes, suspending services temporarily, and maintaining low speeds under hazardous conditions are critical. Monitoring road conditions and issuing real-time updates to clients improves safety and trust. Truck drivers are advised to cross flooded areas cautiously, secure cargo tightly, and avoid sudden maneuvers.

Track-and-trace systems can experience communication disruptions, leading to outdated shipment status updates. Inventory tracking becomes challenging during prolonged network instability. Investing in digital platforms with real-time alerts, redundant communication channels, and contingency plans enhances transparency and decision-making under duress.

Implementing multi-sourcing and multi-modal transport options diminishes risk concentration. Strategically located buffer inventories and warehouses improve responsiveness. Regular risk assessments, emergency drills, and investment in infrastructure hardening — such as elevated container yards and weather-resilient warehouses — fortify logistics against climate extremes. AI-driven predictive analytics enable proactive route adjustments and resource allocation.

Transparent, frequent communication, via email, SMS, or app notifications, informs clients about expected delays, alternate routing, and revised delivery times. Managing expectations early helps sustain trust and loyalty even amidst uncertainty.

Recovery hinges on port capacity, availability of skilled workforce, and infrastructure robustness. Pre-established emergency response protocols coupled with logistic flexibility dramatically compress downtime. Companies like Walmart have demonstrated rapid logistics recovery by activating emergency plans and collaborating closely with local communities post-hurricanes.

Standard cargo insurance often covers physical loss or damage from natural disasters, but coverage for delays varies by policy. Businesses should review policies carefully and may opt for additional natural disaster delay coverage or storage risk insurance tailored to typhoon-prone regions to mitigate financial exposure.